Advanced Instrumentation

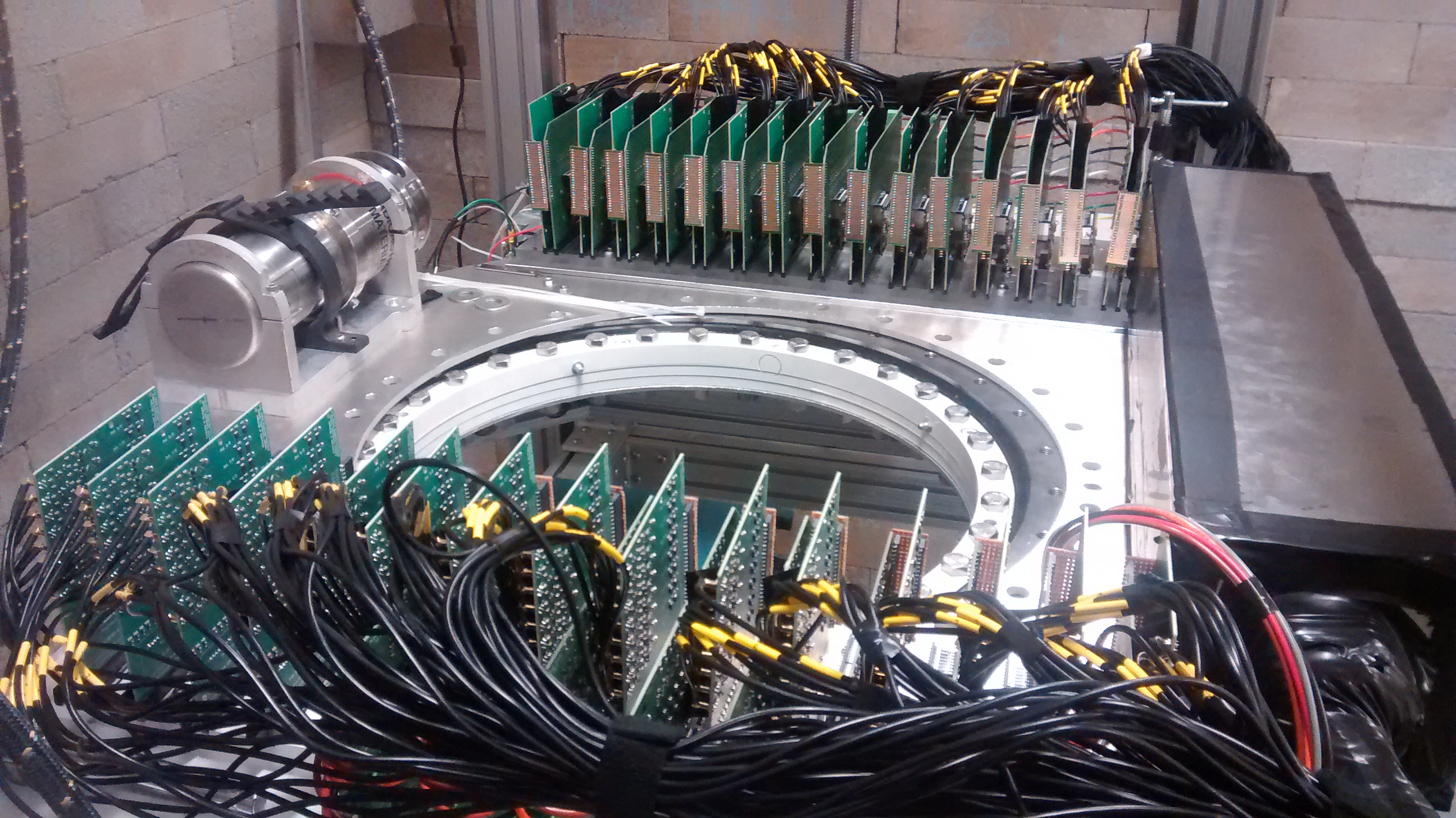

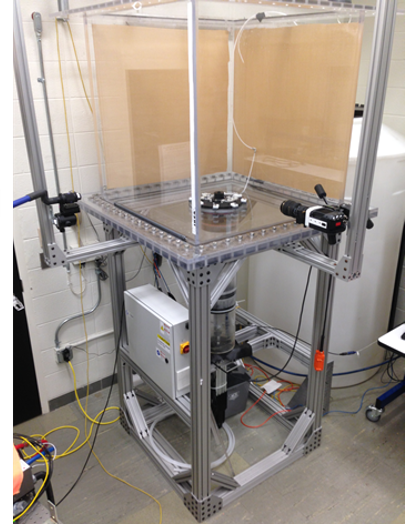

We have developed an in-house tomography system that allows to image test sections with a spatial resolution of 1mm. The system can be operated remotely through WiFi.

We have developed an in-house tomography system that allows to image test sections with a spatial resolution of 1mm. The system can be operated remotely through WiFi.

For more info click here.

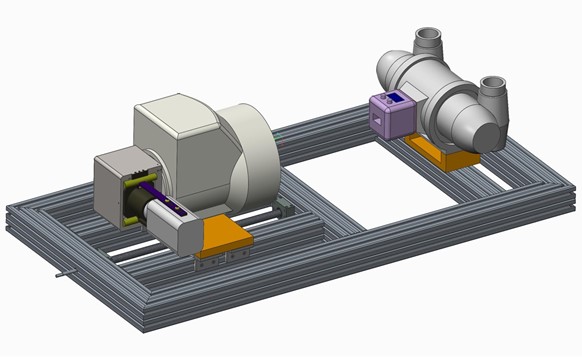

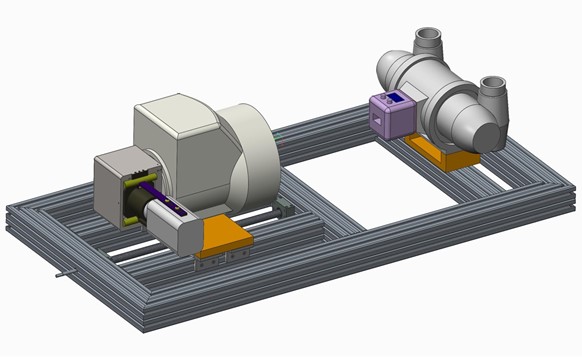

A customized high-speed Xray system has been put together that allows imaging with up to 1000 frames/s. The xray tube has a focal spot of 0.6 mm, a voltage of up to 150 KV and a power of 80 kW. Imaging is done using an image intensifier coupled with a high-speed camera, a linear detector and 2D detector panels.

A customized high-speed Xray system has been put together that allows imaging with up to 1000 frames/s. The xray tube has a focal spot of 0.6 mm, a voltage of up to 150 KV and a power of 80 kW. Imaging is done using an image intensifier coupled with a high-speed camera, a linear detector and 2D detector panels.

For more info click here.

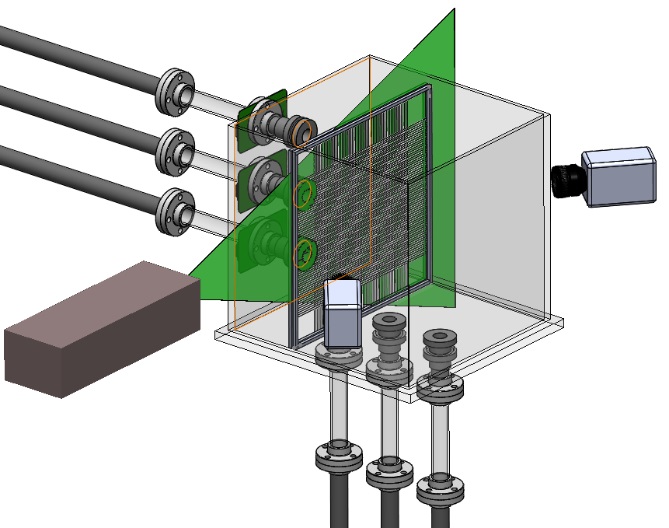

An Xray tube combined with a high-resolution imaging system is mounted on a rotating table with large diameter to allow for imaging of test sections.

An Xray tube combined with a high-resolution imaging system is mounted on a rotating table with large diameter to allow for imaging of test sections.

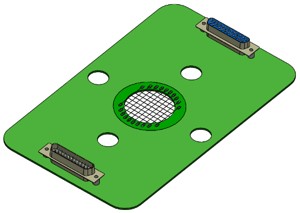

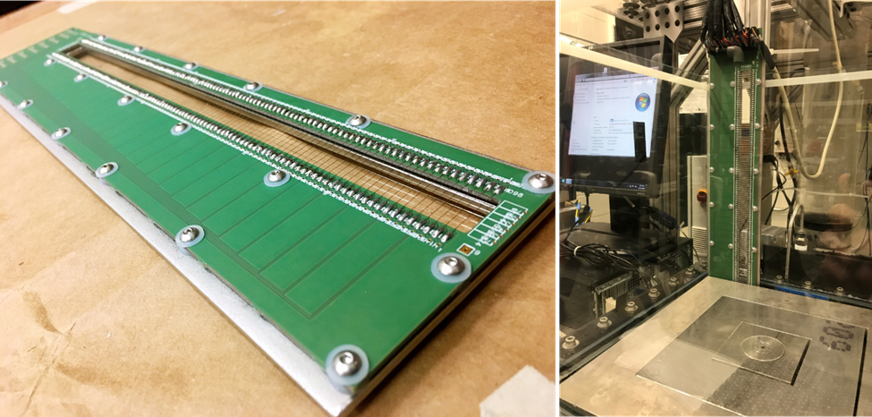

We design and build wiremesh sensors to fit a variety of test sections. The sensors allow to measure the instantaneous fluid conductivity on a matrix of up to 128×128 locations and up to 10,000 frame/s.

We design and build wiremesh sensors to fit a variety of test sections. The sensors allow to measure the instantaneous fluid conductivity on a matrix of up to 128×128 locations and up to 10,000 frame/s.

For more info click here.

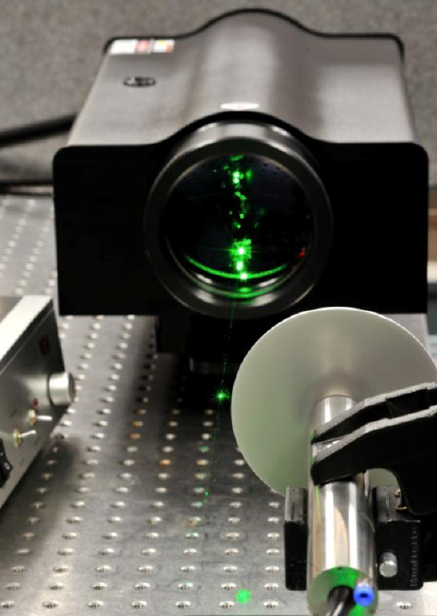

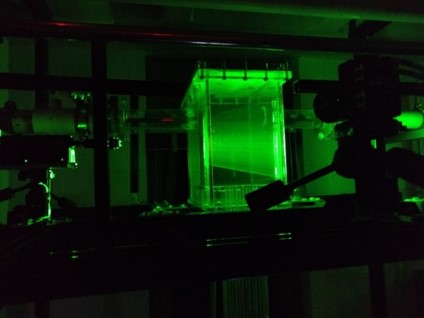

The ECMF group uses Laser Doppler Velocimetry (LDV) for accurate monitoring of boundary conditions (velocity profile) at the inlet of our test sections. Accurate characterization of boundary conditions is crucial for validation of CFD (computational fluid dynamics) models.

The ECMF group uses Laser Doppler Velocimetry (LDV) for accurate monitoring of boundary conditions (velocity profile) at the inlet of our test sections. Accurate characterization of boundary conditions is crucial for validation of CFD (computational fluid dynamics) models.

Experimental Facilities

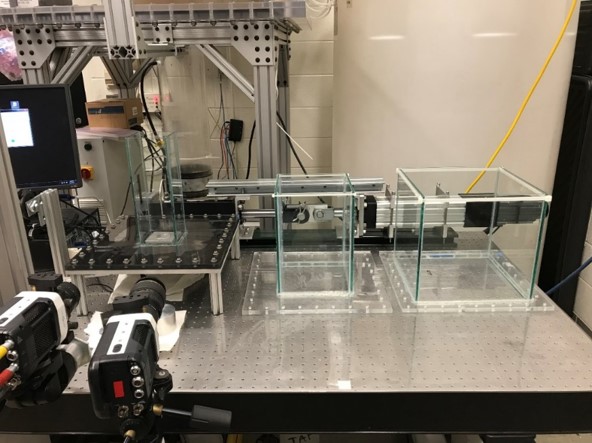

The facility is used to investigate the propagation of stratified fronts. It is equipped with high-resolution instrumentation including Particle Image Velocimetry (PIV) and Wiremesh sensors.

The facility is used to investigate the propagation of stratified fronts. It is equipped with high-resolution instrumentation including Particle Image Velocimetry (PIV) and Wiremesh sensors.

For more info click here.

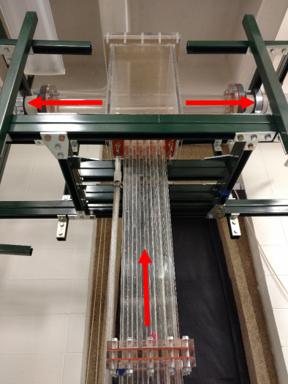

The facility is used to investigate the interaction of buoyant jets with stratified environments. A wiremesh sensor is used to measure the fluid density distribution. PIV and PLIF are used for measurements of the velocity field and concentration fields respectively.

The facility is used to investigate the interaction of buoyant jets with stratified environments. A wiremesh sensor is used to measure the fluid density distribution. PIV and PLIF are used for measurements of the velocity field and concentration fields respectively.

For more info click here.

A scaled facility of the DESTROJER setup is used to investigate scaling effects in the interactions between buoyant jets and stratified environments. This setup is equipped with wiremesh sensors, PIV and PLIF.

A scaled facility of the DESTROJER setup is used to investigate scaling effects in the interactions between buoyant jets and stratified environments. This setup is equipped with wiremesh sensors, PIV and PLIF.

For more info click here.

A scaled, separate effect facility was built to model the upper plenum of the Reactor Core Cavity Cooling System (RCCS). The setup allows to investigate the interaction of up to 6 rectangular jets. The facility is equipped with PIV.

A scaled, separate effect facility was built to model the upper plenum of the Reactor Core Cavity Cooling System (RCCS). The setup allows to investigate the interaction of up to 6 rectangular jets. The facility is equipped with PIV.

For more info click here.

The loop has been designed to investigate turbulence-induced thermal fatigue in isolated branch lines. The setup is equipped with wiremesh sensors, film sensors, PIV and LDV.

The loop has been designed to investigate turbulence-induced thermal fatigue in isolated branch lines. The setup is equipped with wiremesh sensors, film sensors, PIV and LDV.

For more info click here.

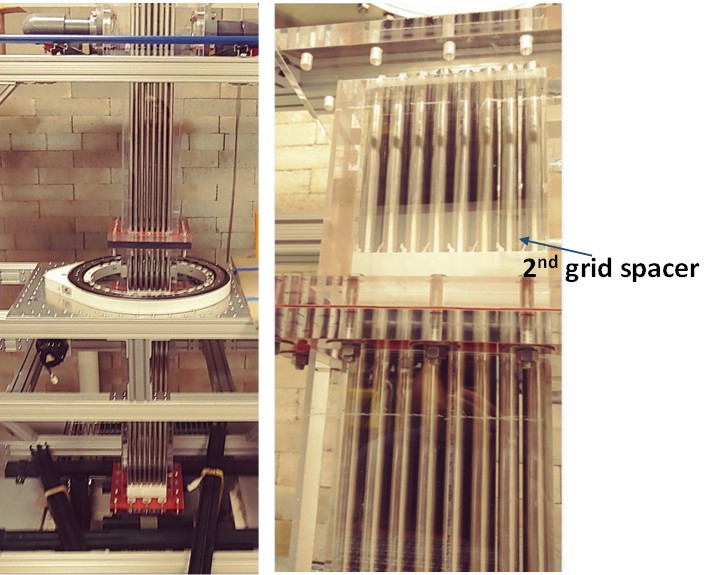

An adiabatic fuel bundle has been built to measure detailed void-fraction distributions and investigate the effects of grid spacers with mixing vanes and partial-length rods. The setup is equipped with high-resolution gamma tomography and wiremesh sensors.

An adiabatic fuel bundle has been built to measure detailed void-fraction distributions and investigate the effects of grid spacers with mixing vanes and partial-length rods. The setup is equipped with high-resolution gamma tomography and wiremesh sensors.

For more info click here.

This facility is aimed at investigating two-phase flow regimes in a helical coil. the setup is equipped with a high-speed camera and with high-speed Xray radiography system.

This facility is aimed at investigating two-phase flow regimes in a helical coil. the setup is equipped with a high-speed camera and with high-speed Xray radiography system.

For more info click here.

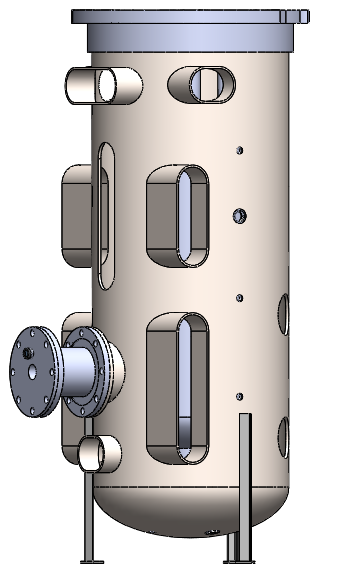

An experimental facility is currently being built to investigate small and medium sized DLOFC (Depressurized Loss of Forced Cooling) accidents in High Temperature Gas Reactors.

An experimental facility is currently being built to investigate small and medium sized DLOFC (Depressurized Loss of Forced Cooling) accidents in High Temperature Gas Reactors.

The General Atomics GT-MHR design is used as reference for the facility, using a 1/20th scaling factor.

High-resolution measurements are planned using PIV and PLIF to to gain insight in the He/air mixing phenomena associated with small and medium DLOFC accidents.